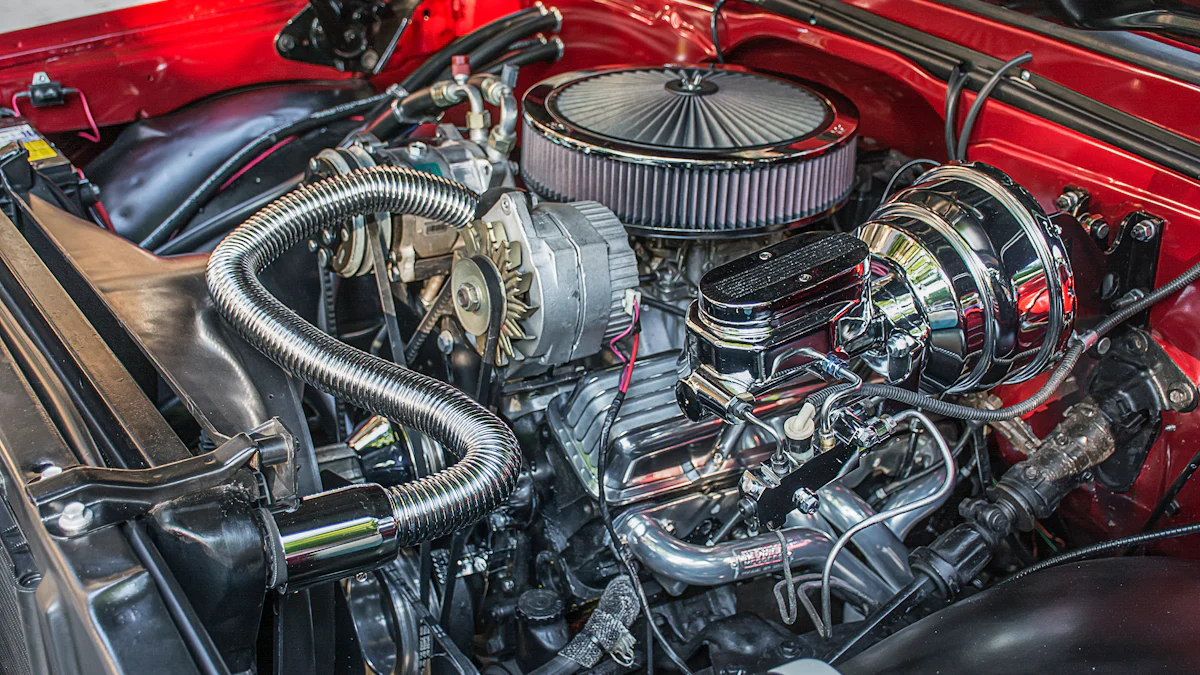

Engine performance plays a crucial role in the overall functionality and efficiency of a vehicle. Various components work together to optimize this performance, ensuring smooth operation and longevity. Among these components, the harmonic balancer stands out as a key player. This device minimizes torsional crankshaft harmonics and resonance, contributing significantly to engine reliability and power.

Understanding the Harmonic Balancer

Definition and Basic Function

A harmonic balancer, also known as a crankshaft damper, is a circular disc attached to the crankshaft. This component absorbs vibrations caused by the engine’s firing cylinders. The harmonic balancer includes a counterweight to externally balance the rotating assembly. This device plays a crucial role in maintaining engine stability and performance.

Historical Development and Evolution

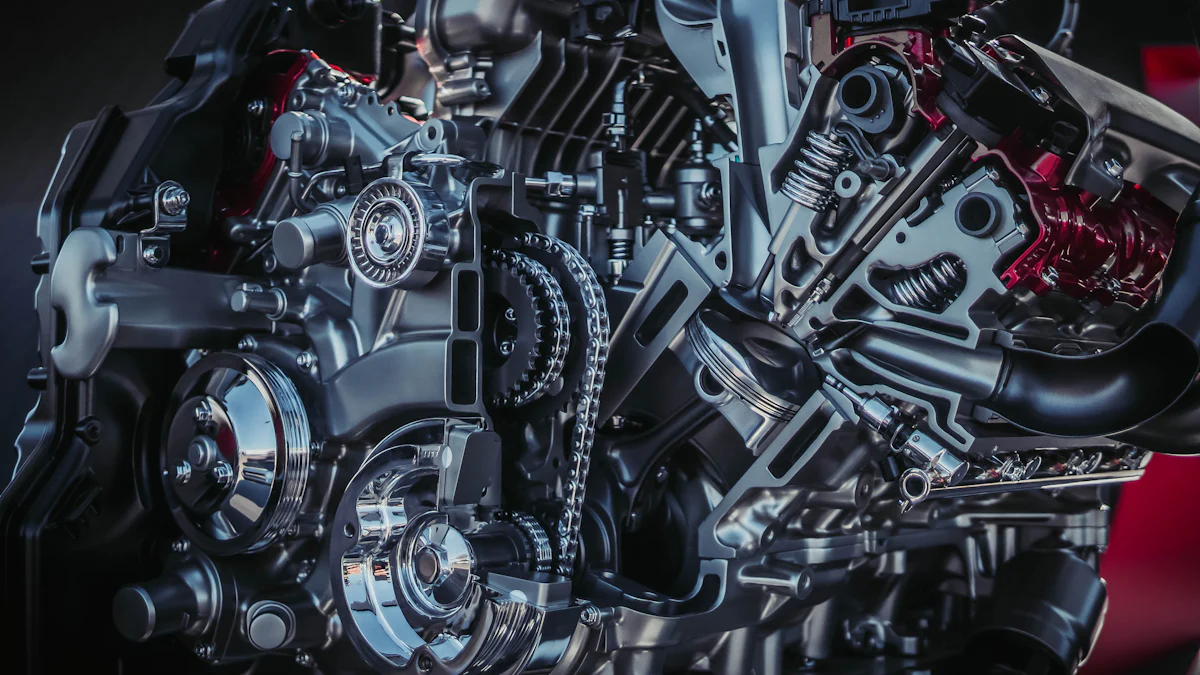

The concept of the harmonic balancer has evolved over time. Early engines lacked this component, leading to frequent crankshaft failures. Engineers introduced the harmonic balancer to address these issues. Modern harmonic balancers now incorporate advanced materials like rubber and metal to enhance their effectiveness. These improvements have significantly increased engine longevity and reliability.

How Does a Harmonic Balancer Work?

Mechanics of Vibration Dampening

The harmonic balancer functions by dampening torsional vibrations. These vibrations occur due to the firing of the engine cylinders. The balancer’s rubber and metal construction absorbs these vibrations, reducing stress on the crankshaft. This process ensures smoother engine operation and prevents potential damage.

Interaction with the Crankshaft

The harmonic balancer attaches directly to the crankshaft. When the engine runs, the balancer rotates with the crankshaft. This rotation allows the balancer to counteract the torsional forces generated by the engine. By doing so, the harmonic balancer minimizes the risk of crankshaft failure and enhances overall engine performance.

Common Misconceptions

Misunderstanding its Role

Many people misunderstand the role of the harmonic balancer. Some believe it only balances the crankshaft. However, the primary function involves absorbing and dampening vibrations. This misconception can lead to neglecting the importance of maintaining the harmonic balancer.

Myths about Maintenance

Several myths surround the maintenance of the harmonic balancer. One common myth suggests that the balancer requires no regular maintenance. In reality, regular inspection and timely replacement are essential. Neglecting the harmonic balancer can result in severe engine damage, including crankshaft failure.

Importance of a Harmonic Balancer in Engine Performance

Reducing Engine Vibration

Impact on Engine Longevity

A harmonic balancer plays a pivotal role in extending engine longevity. Vibrations from the engine’s firing cylinders can cause significant wear and tear on the crankshaft and other components. The harmonic balancer absorbs these vibrations, reducing stress on the crankshaft. This reduction in stress prevents premature failure and extends the life of the engine.

Influence on Smooth Operation

Smooth engine operation relies heavily on the harmonic balancer. By dampening torsional vibrations, the harmonic balancer ensures that the engine runs smoothly. This smooth operation translates to a more comfortable driving experience and less strain on the vehicle’s components. The absence of excessive vibrations also contributes to quieter engine performance.

Enhancing Power Output

Balancing the Crankshaft

The harmonic balancer is essential for balancing the crankshaft. An imbalanced crankshaft can lead to inefficient engine operation and reduced power output. The harmonic balancer counteracts these imbalances, allowing the engine to operate at optimal efficiency. This balance ensures that the engine utilizes its full potential, resulting in enhanced power output.

Improving Fuel Efficiency

Fuel efficiency improves significantly with a properly functioning harmonic balancer. By maintaining engine stability and reducing vibrations, the harmonic balancer allows the engine to run more efficiently. Efficient engine operation means better fuel combustion, which leads to improved fuel economy. Vehicle owners will notice fewer trips to the gas station and lower fuel costs.

Preventing Engine Damage

Avoiding Crankshaft Failure

Crankshaft failure poses a severe risk to engine health. The harmonic balancer helps prevent this by absorbing harmful vibrations that could otherwise damage the crankshaft. Without a harmonic balancer, the crankshaft would be subjected to continuous stress, increasing the likelihood of failure. Regular maintenance of the harmonic balancer is crucial to avoid such catastrophic damage.

Protecting Other Engine Components

The harmonic balancer also protects other engine components. Vibrations not only affect the crankshaft but also impact other parts like the drive belt and engine-driven accessories. A failing harmonic balancer can lead to damage in these areas, resulting in costly repairs. Ensuring the harmonic balancer remains in good condition safeguards the entire engine system.

Maintenance and Troubleshooting

Signs of a Failing Harmonic Balancer

Unusual Noises

Unusual noises often indicate a failing harmonic balancer. A thumping sound may come from the pulley bolts surrounded by rubber. This noise results from wear in the rubber separating the two halves of the balancer. Regularly listening for such sounds can help identify issues early.

Visible Wear and Tear

Visible wear and tear on the harmonic balancer also signal potential problems. Inspect the rubber and metal components for cracks or deterioration. The back side of the balancer, where the rubber tends to wear out, should receive particular attention. Addressing visible damage promptly can prevent more severe engine issues.

Regular Maintenance Tips

Inspection Frequency

Regular inspections play a vital role in maintaining the harmonic balancer. Experts recommend setting a consistent schedule for these inspections. Frequent checks allow for early detection of wear and potential failures. Following manufacturer guidelines ensures the harmonic balancer remains in optimal condition.

Replacement Guidelines

Replacing the harmonic balancer at the first sign of significant wear is crucial. Manufacturers provide specific replacement intervals based on usage and environmental factors. Adhering to these guidelines helps maintain engine performance and longevity. Always replace both the pulley and balancer simultaneously to ensure proper function.

Troubleshooting Common Issues

Diagnosing Vibration Problems

Diagnosing vibration problems involves monitoring for unusual vibrations. Excessive vibrations may indicate an imbalance within the harmonic balancer. Properly functioning balancers minimize vibrations and maintain engine stability. Investigate any deviations from normal vibration patterns promptly to prevent further complications.

Professional vs. DIY Repairs

Deciding between professional and DIY repairs depends on the complexity of the issue. Simple inspections and minor replacements can often be handled by vehicle owners. However, more complex problems may require professional expertise. Professionals ensure proper alignment and installation, which are critical for the harmonic balancer’s functionality and longevity.

The harmonic balancer plays a crucial role in enhancing engine performance. Regular maintenance and prompt troubleshooting ensure optimal functionality. A well-maintained harmonic balancer reduces vibrations, extends engine longevity, and improves fuel efficiency. As Nick Orefice from Fluidampr states:

“High-performance balancers are necessary to prolong the life of your engine. You need a damper that will perform like it should in the most extreme conditions that stock dampers cannot do.”

Investing in a quality harmonic balancer safeguards overall engine health and reliability.

Post time: Jul-22-2024